Scheduling cross-docking operations: Integration of operational uncertainties and resource capacities.

Abstract

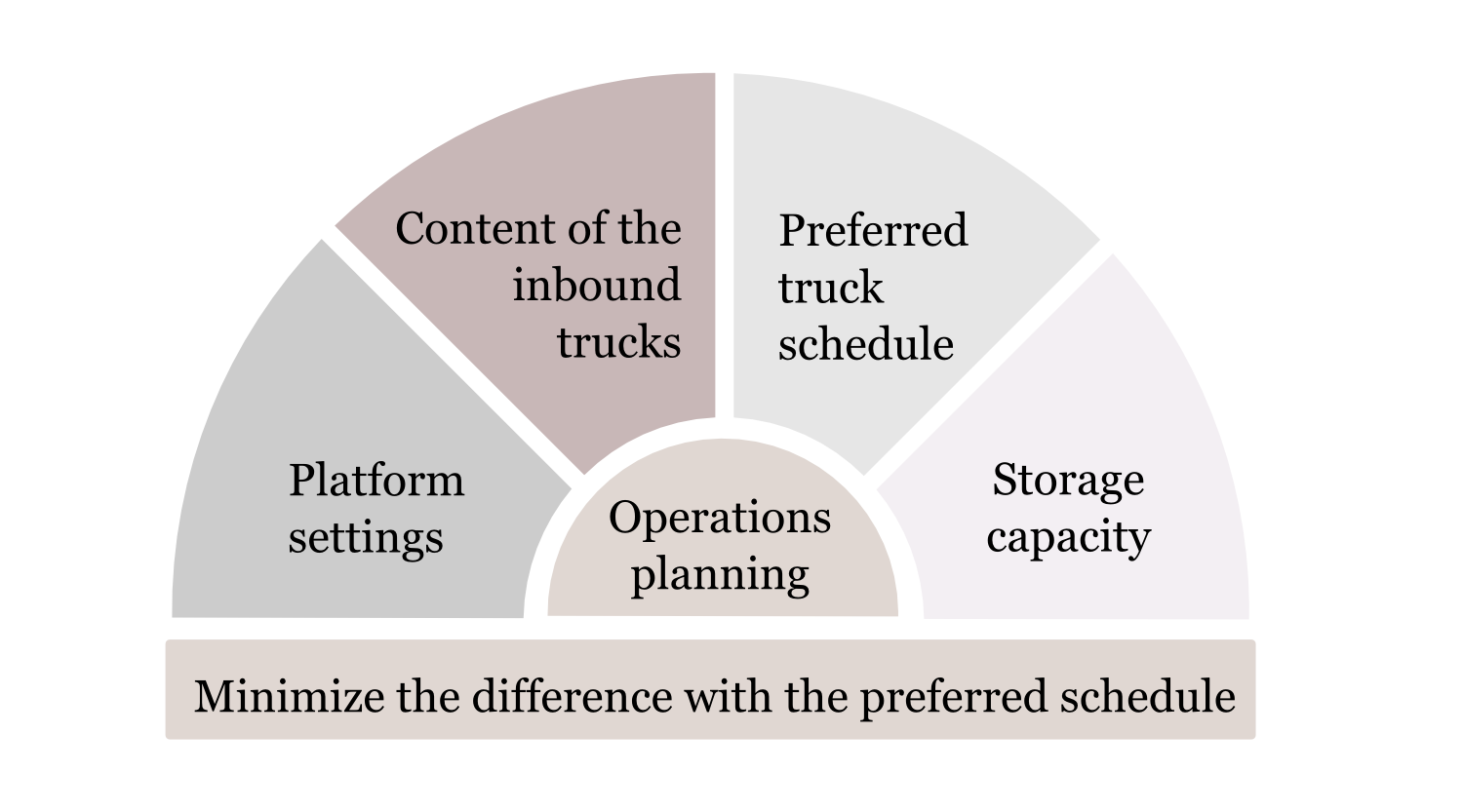

In a cross-docking platform, goods are unloaded from inbound trucks, sorted and directly reloaded in outbound trucks -- each product typically stays less than 24 hours in the platform. By analyzing the gaps between the literature and on-field observations, we highlight two research directions: accounting for operational uncertainties, and for the human resource capacity in the platform.A truck scheduling problem with time windows for the inbound and outbound trucks is modeled with an integer program and solved with three different heuristics. The robustness of the schedules obtained is then tested with a discrete-event simulation model, which enables to evaluate several robust reformulations of the initial model.

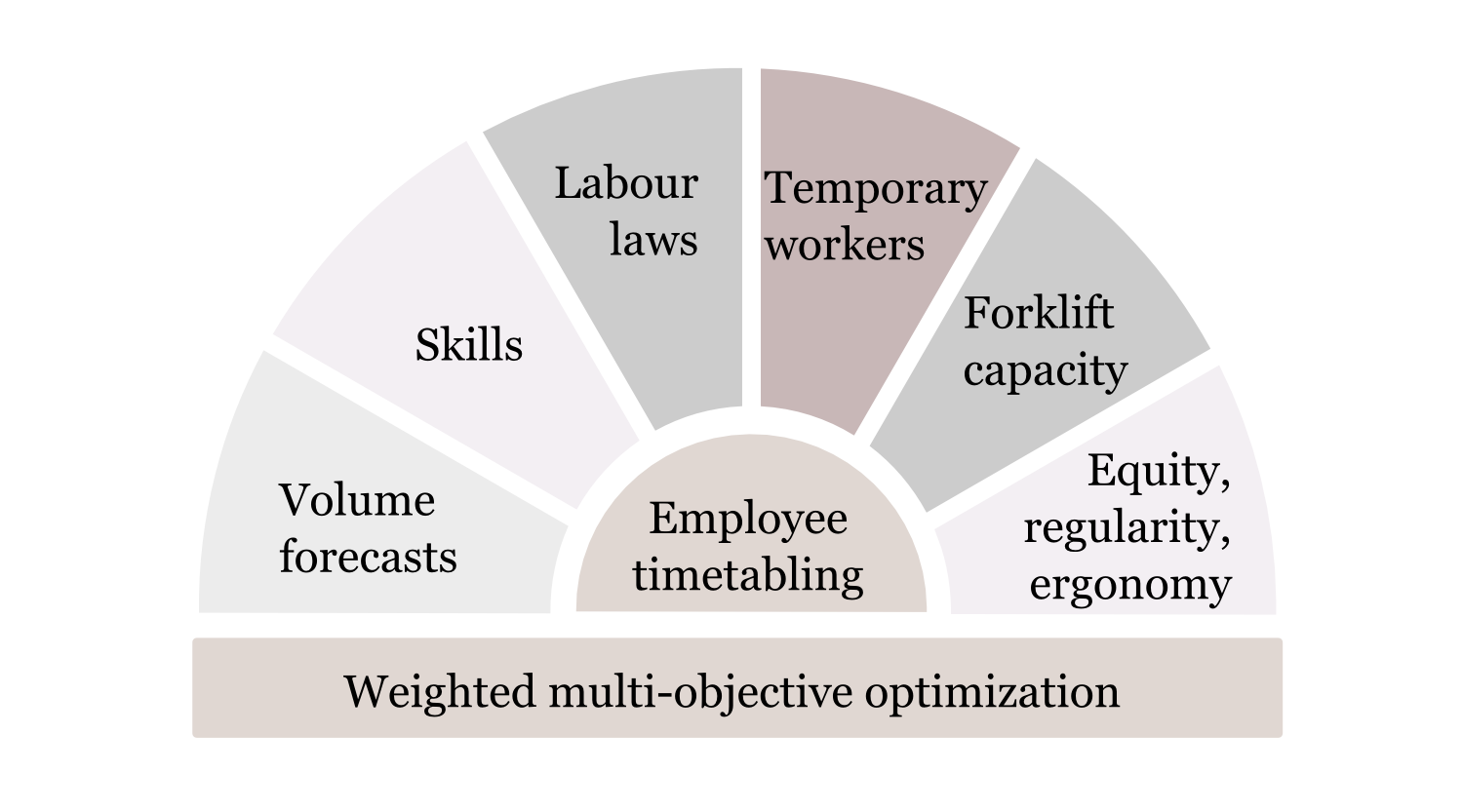

The employee timetabling and rostering problem in the platform is addressed with three mixed integer linear problems solved sequentially. The two models can be combined to serve as a decision-support tool for a cross-docking platform.

Jury composition

- Mrs Luce BROTCORNE - Chargée de Recherche, HDR, INRIA Lille Nord Europe, Reviewer

- Mr Pierre BAPTISTE - Professor, École Polytechnique de Montréal, Reviewer

- Mr Damien TRENTESAUX - Professor, Université de Valenciennes et du Hainaut-Cambrésis, Examiner

- Mr Allen G. GREENWOOD - Professor, Mississippi State University, Examiner

- Mrs Gülgün ALPAN - Maître de conférences, HDR, Grenoble INP, Supervisor

Ma thèse en 180 secondes

Grenoble MT180 competition semi-final, on the 27th of April 2015, Grenoble museum (in French).

More details?

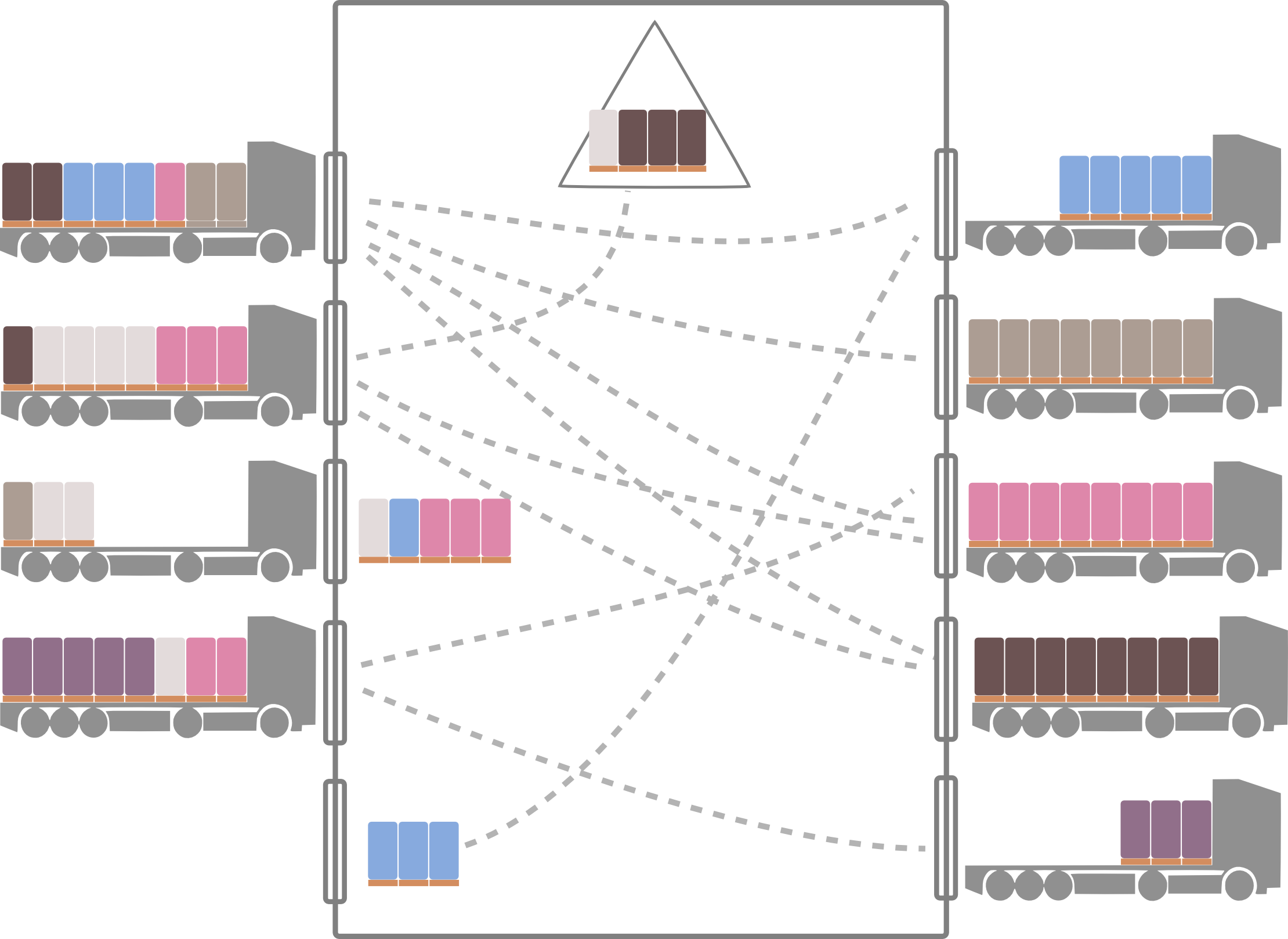

We call cross-docking the process of consolidating products flows that come from different origin but have the same destination, while minimizing the temporary storage (less than 24 hours) and the handling. The logistics operations in a cross-docking platform are : unloading the incoming products, sorting and dispaching them according to their destination, and reloading them in the appropriate truck. Of course, the way those operations are carried depends on the activity field - retail, parcels, perishables...

The cross-docking technique is relatively new. To tackle this hard problem, researchers have made important simplifying assumptions : they worked on platforms with one inbound and one outbound door, assumed infinite internal resources or zero transfer times. The goal of this thesis is to relax those assumptions, adding constraints closer to the real world ones.

The cross-docking optimization problems include strategic problem, such as finding the best location for a platform in a supply-chain, or the optimal shape and amount of doors for a given platform. The problems we are interested in are on the operational level, i.e. about the daily internal management of the cross-docking platform :

- What truck to unload at what door, at what time?

- What handling task, at what time and with which resources?

Our working plan

- Carry out an academic and industrial benchmark to identify the possible constraints and the optimization directions to focus on.

- Develop models to deal with those objectives and constraints, especially regarding the internal resources and the incertainties on the inbound arrivals.

- Undertake some simulations to test the robustness of our models when exposed to randomness.

Two research directions

Take into account the inbound flows

To plan the handling operations, it is important to have information about the inbound product flow : quantity, product reference, arrival time... However, in many real-life situations, this information is totally or partially unknown: mishaps or delays can force the manager to change the plannings on-line.

We'd like our models to be as robusts as possible against those hazards. Therefore we want to create plannings that are able to take up the unexpected events with a minimimum impact on the global platform organization. Simulation models are developed and used to assess the robustness of our optimization models and compare them.

Plan the internal resources

Matching the resources to the activity volume is a crucial issue in logistics, since a volume is put on a bill but the main expense in the manpower cost. And yet the timetables have to include many factors: the operators' qualifications, the cost of hiring temporary workers, the existing laws and regulations, the amount of forkliftf trucks available, the ergonomy issues, the equity and regularity of the planning obtained...

The decision-support tool we developed inputs all those data, including the volumes forecast, and automatically creates the weekly and daily timetables of a logistics platform.